Welcome To YAFEI MACHINERY Website

- YAFEI

- Electric furnace

- Yes

Pit gas nitriding furnace is mainly used for gas nitriding heat treatment of various steel mechanical parts, ...

brief introduction :

Pit gas nitriding furnace is mainly used for gas nitriding heat treatment of various steel mechanical parts, automobile curved glaze, motorcycle brake pads, molds, etc.

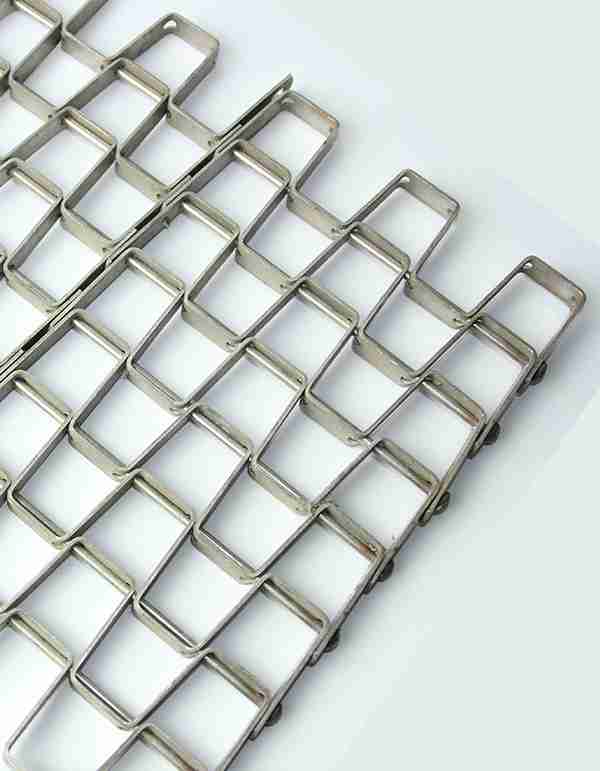

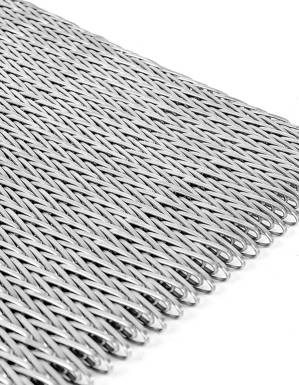

Adopt energy-saving furnace village double water-cooled furnace tank cover, vacuum rubber seal and temperature control in the upper, middle and lower three zones. The heat preservation of the electric furnace, the uniformity of the furnace temperature, the sealing performance and the nitriding speed are greatly improved. The shell of this series of well-type gas nitriding furnace is welded by steel plate and section steel. The furnace lining is made of ultra-light, high-strength 0.6 type energy-saving refractory bricks. The outer layer of the furnace lining is sandwiched with aluminum silicate fiber insulation cotton. The heating element is wound into a V shape by a high-temperature resistance band and installed on the furnace wall brick; stainless steel furnace pot. A double-head stainless steel dripper is installed on the furnace cover for dripping the nitriding medium to make the temperature and atmosphere in the furnace uniform. The furnace cover is equipped with a sampling pipe, an exhaust pipe, and a decomposition rate tester. The furnace tank and the furnace cover are sealed with water-cooled vacuum rubber and equipped with compression bolts. The exhaust gas in the furnace is discharged out of the furnace through the exhaust pipe.

Application: