Welcome To YAFEI MACHINERY Website

- YAFEI

- Electric furnace

- Yes

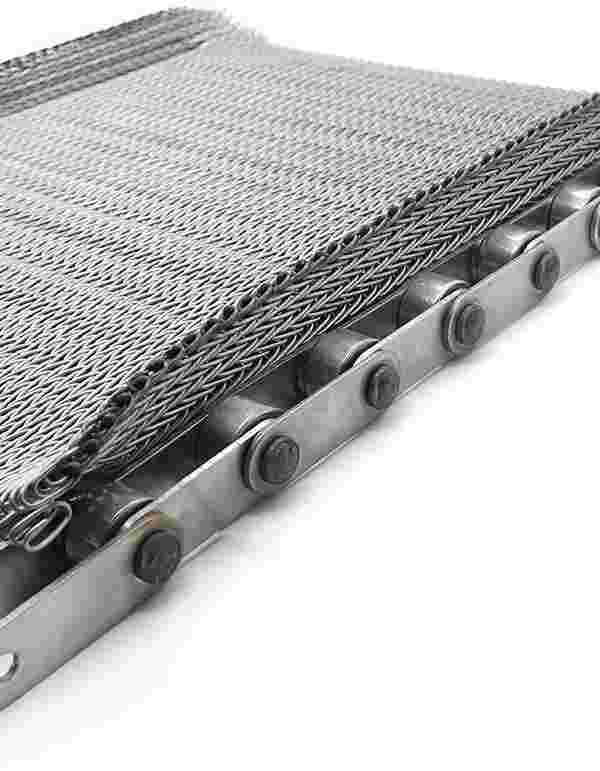

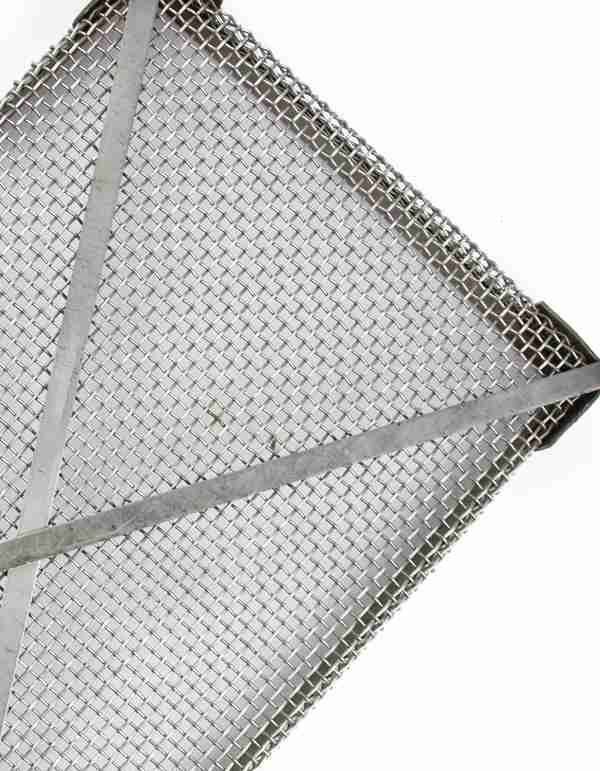

The working principle of the continuous carburizing furnace is to slowly feed the parts into the sealed furna...

brief introduction :

The working principle of the continuous carburizing furnace is to slowly feed the parts into the sealed furnace body from the mesh belt, and add stupid, alcohol and ammonia at a high temperature of 900 degrees Celsius. Alcohol combustion prevents oxygen from entering the furnace to oxidize the workpiece. Carbon is contained in the stupid, and carbon is contained in ammonia, which produces a carbonitriding effect under the high temperature environment of the furnace.

The carburizing furnace is a new type of energy-saving cycle-operated heat treatment electric furnace, which is mainly used for gas carburizing of steel parts. Ultra-light energy-saving furnace lining material (ceramic fiber) and advanced integrated water-cooled furnace sealing fan are selected. This series of carburizing furnaces have uniform furnace temperature, fast heating, good heat preservation, faster workpiece carburization, uniform carbon potential atmosphere, and carburization Even when the furnace pressure is increased, there is no leakage, which improves the production efficiency and carburizing quality.

Application: